How to Measure Carbon Emissions: GHG Protocol Explained - Scope 1

Greenhouse gas (GHG) accounting is a fundamental part of climate change mitigation and corporate sustainability strategies. GHG Protocol is one of the most widely adopted frameworks for corporate emissions inventory across organisational activities. Under this framework, emissions are classified into three scopes based on their sources and levels of organisational control. This article focuses on the first of the three.

Scope 1: Direct GHG Emissions

Direct GHG emissions come from sources that they own or control. Understanding the nature of Scope 1 emissions is essential, as they are directly influenced by operational decisions and often present the most immediate opportunities for emissions reduction. Scope 1 emissions result from four types of sources which are stationary combustion, mobile combustion, process emissions, and fugitive emissions.

Stationary Combustion

Stationary combustion is defined as the process of rapid oxidation of substances (i.e. fuels) of a non-mobilised unit(1). During this process, greenhouse gases are formed and emitted (if not captured or controlled) which is then called stationary combustion emission. In a complete combustion reaction of hydrocarbons, carbon dioxide (CO2) holds the vast fraction of the gas emitted, with a little fraction of methane (CH4), carbon monoxide (CO), and non-methane volatile organic compounds (NMVOCs) for a typical stationary combustion. On the other hand, the incomplete combustion process results in higher CO fractions.

Stationary combustion emissions may be quantified through direct measurement and estimation methods using activity data. Direct measurements generally take the form of continuous emissions monitoring (CEM) that allow real time CO2 flow rate and concentrations of exhaust gases in a duct. However, direct measurement may not capture the other gases since the amount of CO2 emitted is measured before the carbon in the CH4, CO, and NMVOC molecules have been oxidized in the atmosphere to CO2. In contrast, using estimation calculation methods, these emissions can be estimated separately.

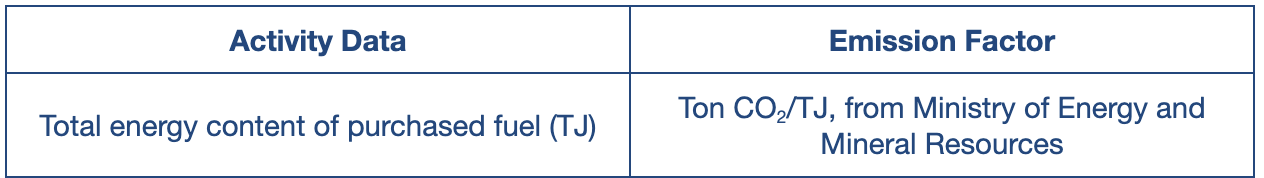

To conduct estimation calculation, the record of activity data should be collected. The data consists of the fuel volume purchased by the company is converted to mass using fuel density (kg/m3), and then converted to energy content (TJ) using net calorific value (TJ/Gg). Energy content will be used as the activity data. The emission factor used can refer to national values provided by the Indonesian Ministry of Energy and Mineral Resources in ton CO2/TJ unit.

Process Emissions

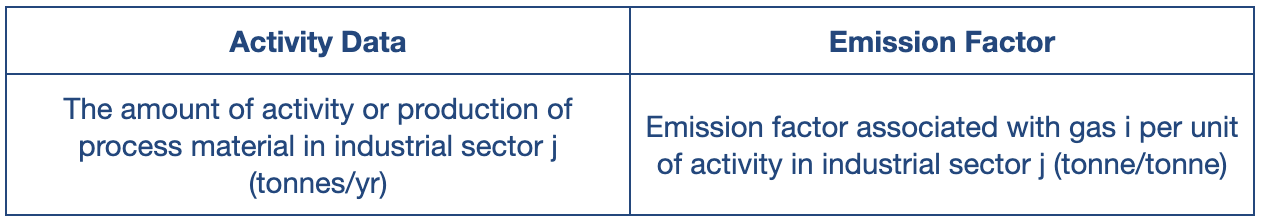

Greenhouse gases are formed through a variety of industrial activities. Process emissions result from physical or chemical reactions of a manufacturing or industrial process, in contrast to emissions from burning fossil fuels. This means process emissions are emitted through material transformation rather than burning fuel for energy. Process emissions are typically associated with specific industries, such as the calcination step in cement manufacturing, CO2 from catalytic cracking in petrochemical processing, PFC emissions from aluminum smelting, etc. Some examples of activity data and emission factors of process emissions are shown in the table below.

Mobile Combustion

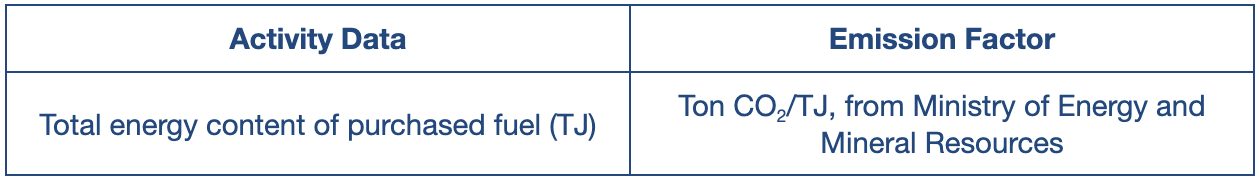

Mobile combustion emissions result from the use of fuels in transportation devices such as automobiles, trucks, buses, trains, airplanes, boats, ships, barges, and vessels. The calculation process is similar to that of stationary combustion. Data of fuel volume purchased by the company is converted to mass using fuel density (kg/m3), and then converted to energy content (TJ) using net calorific value (TJ/Gg). Energy content will be used as the activity data. The emission factor used can refer to national values provided by the Indonesian Ministry of Energy and Mineral Resources in ton CO2/TJ unit.

Fugitive Emissions

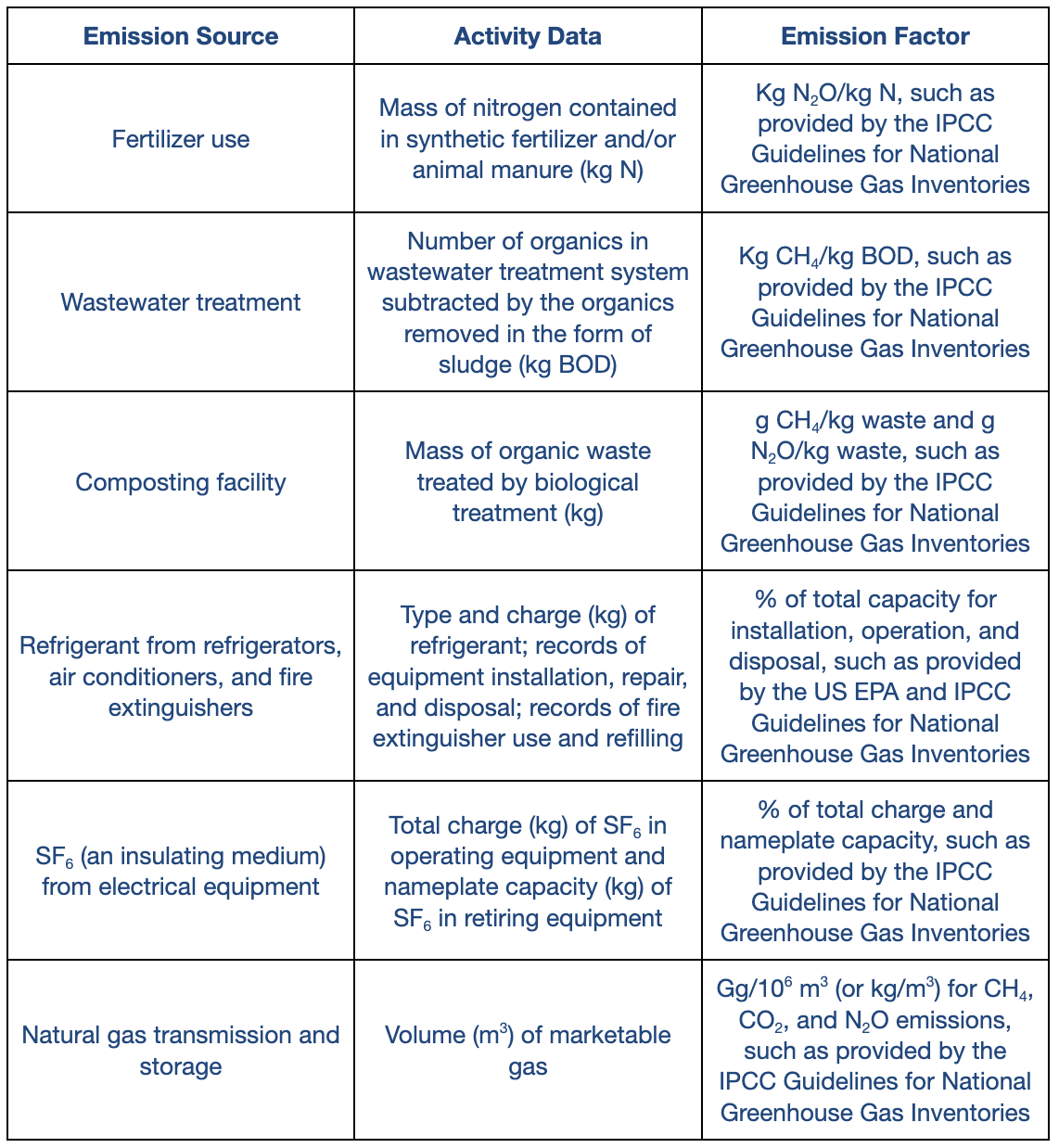

Fugitive emissions come from intentional and unintentional releases such as equipment leaks, coal piles, wastewater treatment, pits, cooling towers, and gas processing activities. One of the most common equipment leaks are from air conditioners, refrigerators, and fire extinguishers. Refrigerants are released during installation, service, disposal, and throughout its lifetime. Fire suppressants are also emitted when used to extinguish fire and during refilling. Gases used in these equipment are usually hydrofluorocarbons (HFCs), and the global warming potential (GWP) varies widely according to the type of HFC. Some fire extinguishers use CO2 as the fire suppressant. However, some fire extinguishers use dry chemical powder with nitrogen gas as its propellant, thus not emitting greenhouse gases. Examples of activity data and emission factors of fugitive emissions are outlined below.

Understanding and accurately accounting for Scope 1 emissions is a critical first step in building a credible corporate GHG inventory. Because these emissions come from sources directly owned or controlled by an organisation, they represent the most immediate opportunities for operational improvements and emission reductions. Keep an eye out for the next part where we will be discussing the other two scopes.

References

Bhatia, P., Ranganathan, J., & World Business Council for Sustainable Development (WBCSD). (2004). The Greenhouse Gas Protocol. Retrieved from https://www.wri.org/research/greenhouse-gas-protocol-0

Gillenwater, M. (2005). Calculation tool for direct emissions from stationary combustion version 3.0. Retrieved from https://ghgprotocol.org/sites/default/files/2023-02/Stationary_Combustion_Guidance_final_1_0.pdf

Revised 1996 IPCC Guidelines for National Greenhouse Gas Inventories: Reference Manual, CHAPTER 2 INDUSTRIAL P ROCESSES. (n.d.). Retrieved from https://www.ipcc-nggip.iges.or.jp/public/gl/guidelin/ch2ref2.pdf

University of Wisconsin. (n.d.). Retrieved from https://ehs.wisc.edu/fire-life-safety/fire-extinguishers/